If you are in India and looking for a solution to improve your polishing and grinding processes, then you have come to the right place. In this article, we will introduce you to the 6 Axis Industrial Robotic Arm, a powerful tool that offers great accuracy and speed for polishing and grinding tasks. We will also discuss the different types of industrial robots available in the market. So, let’s dive in!

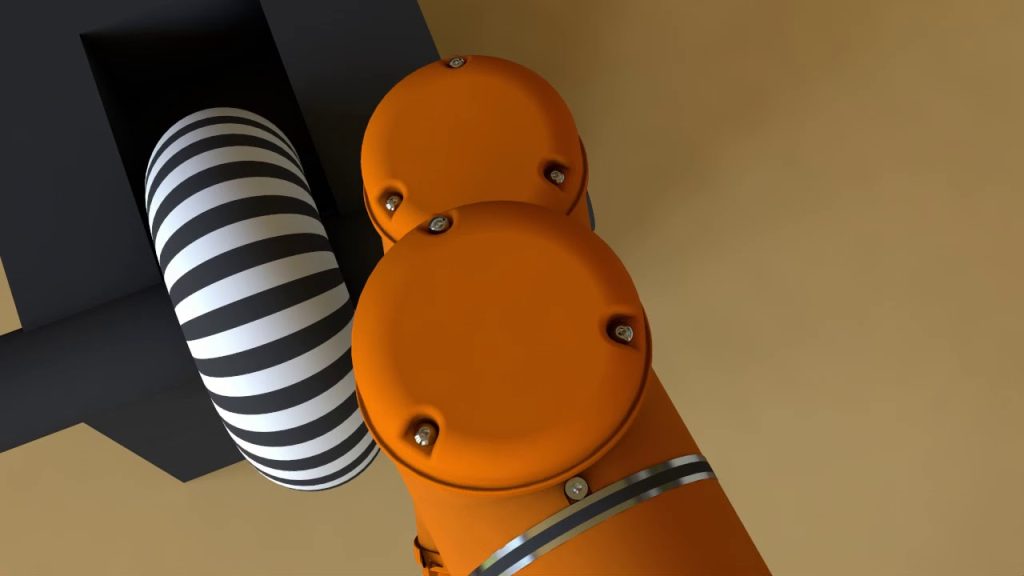

Industrial robots have revolutionized various industries by automating repetitive tasks and improving efficiency. When it comes to polishing and grinding, the 6 Axis Industrial Robotic Arm is a game-changer. This robotic arm is equipped with six axes, allowing it to move freely in multiple directions. With a precision of 10 microns, it ensures a high level of accuracy in every polishing and grinding operation.

One of the key advantages of the 6 Axis Industrial Robotic Arm is its speed. It can perform tasks at an incredible pace, significantly reducing production time. This makes it an ideal choice for industries that require fast and efficient polishing and grinding processes.

Now, let’s talk about the different types of industrial robots available in the market. Industrial robots can be categorized based on their structure and functionality. Some of the common types include:

1. Cartesian Robots: These robots have three linear joints, allowing them to move along three orthogonal axes. They are known for their simplicity and precision.

2. Delta Robots: Delta robots are highly efficient and are often used in high-speed pick and place operations. They are characterized by a parallel linkage mechanism that enables fast and accurate movements.

3. SCARA Robots: SCARA stands for Selective Compliance Assembly Robot Arm. These robots have a vertical axis that allows them to move in a circular motion. They are commonly used in assembly and packaging processes.

4. Articulated Robots: Articulated robots have multiple rotary joints, mimicking the movement of a human arm. They are versatile and can perform complex tasks with ease. These robots are widely used in industries such as automotive and electronics.

5. Collaborative Robots: Collaborative robots, also known as cobots, are designed to work alongside humans. They are equipped with advanced sensors and safety features to ensure a safe working environment. Cobots are flexible and can be easily programmed to perform various tasks.

Now that you are familiar with the different types of industrial robots, it’s time to consider integrating the 6 Axis Industrial Robotic Arm into your polishing and grinding processes. With its impressive accuracy and speed, this robotic arm can revolutionize your production line, increasing productivity and reducing costs.

In conclusion, the 6 Axis Industrial Robotic Arm for polishing and grinding in India offers a great solution for industries looking to enhance their processes. Its high accuracy of 10 microns and impressive speed make it a valuable asset for any manufacturing facility. Additionally, understanding the various types of industrial robots available in the market can help you make an informed decision when choosing the right automation solution for your business.

Check the coil packing solution with leading manufacturers for the professional solution just here:

Remember to remove all the contact information and company names, and ensure that the article is in a friendly and readable format using markdown. Industrial Robot

“Enhancing Precision: Industrial Robotic Arms for Polishing & Grinding in India and an Insight into Various Types of Industrial Robots”