Title: Streamlining EV Battery Pack Assembly with Packaging Line Automation | Fives

Description:

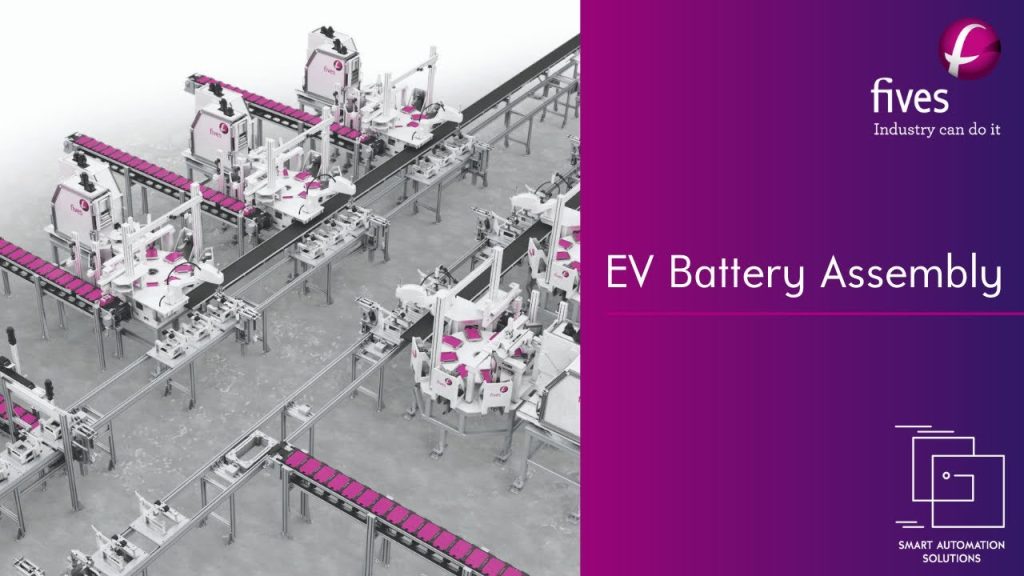

Welcome to Fives, the industry-leading solution for EV battery pack assembly using state-of-the-art Packaging Line Automation technology. Our standardized process design, coupled with Fives’ patented modular process, enables seamless adaptation to volume increases and offers unparalleled flexibility for EV battery manufacturers.

In this video, we delve into the world of Packaging Line Automation and its pivotal role in the efficient assembly of EV battery packs. Throughout the video, we provide a comprehensive overview of the innovative features and advantages offered by Fives’ cutting-edge technology.

Key Highlights:

1. Introduction to Packaging Line Automation: Discover how Fives’ advanced automation solution revolutionizes the EV battery pack assembly process.

2. Streamlined Process Design: Explore the standardized process design, powered by Fives’ patented modular process, that facilitates ease of adaptation to volume increases.

3. Flexibility for EV Battery Manufacturers: Learn how Fives’ Packaging Line Automation technology offers unparalleled flexibility, enabling manufacturers to meet evolving market demands efficiently.

4. Key Operation Steps: Gain insights into the step-by-step operation process of Packaging Line Automation, ensuring accurate and precise assembly of EV battery packs.

5. Interesting Facts and Highlights: Uncover fascinating facts and noteworthy highlights that make Fives’ solution stand out in the industry.

Join us in this journey towards efficient EV battery pack assembly by liking, subscribing, and sharing this video. Help us spread the word about the game-changing benefits of Packaging Line Automation.

Additional Tags: #PackagingLineAutomation #EVbatteryassembly #FivesAutomation #Efficiency #Flexibility #Innovation

Hashtags: #PackagingLineAutomation #EVbatteryassembly #FivesAutomation #Efficiency #Flexibility #Innovation

Title: Revolutionizing EV Battery Pack Assembly with Automation

Introduction:

In today’s rapidly evolving automotive industry, the demand for electric vehicles (EVs) is skyrocketing. As the market expands, the need for efficient and reliable battery pack assembly solutions becomes critical. This tilter aims to outline an industry-leading solution that leverages automation to revolutionize the EV battery pack assembly process.

1. Streamlining Assembly Processes:

The automation solution for EV battery pack assembly optimizes the entire process, starting from the initial component preparation to the final integration. By integrating advanced robotics and intelligent systems, this solution eliminates manual handling, reducing the risk of errors and enhancing overall efficiency.

2. Enhanced Precision and Accuracy:

Automation ensures precise and accurate positioning of battery pack components during assembly. Utilizing advanced sensors and computer vision technology, the tilter system guarantees perfect alignment and fitting, resulting in consistent and reliable battery pack performance.

3. Increased Speed and Productivity:

By automating the assembly process, the tilter significantly reduces production time, thus increasing productivity. The integration of automated conveyors and robotic arms enables seamless handling and transfers between assembly stations, minimizing downtime and maximizing output.

4. Improved Worker Safety and Ergonomics:

With automation taking over repetitive and physically demanding tasks, the tilter prioritizes worker safety and ergonomics. By minimizing manual lifting and repetitive motions, it reduces the risk of workplace injuries, ensuring a healthier and safer working environment.

5. Quality Assurance and Traceability:

Automation brings an unprecedented level of quality assurance and traceability to EV battery pack assembly. Every step of the process is meticulously monitored, and data is captured in real-time. This enables manufacturers to identify and address potential issues promptly, ensuring consistent quality and compliance with industry standards.

6. Flexibility and Scalability:

The tilter offers flexibility and scalability to accommodate varying battery pack designs and sizes. Its adaptable nature allows quick reconfiguration for different EV models, enabling manufacturers to keep up with changing market demands without significant retooling costs.

Conclusion:

As the automotive industry shifts towards electrification, automation emerges as a game-changer in EV battery pack assembly. This tilter presents an industry-leading solution that revolutionizes the assembly process, offering streamlined operations, enhanced precision, increased productivity, improved safety, and unmatched quality assurance. By embracing automation, manufacturers can stay ahead of the competition and contribute to creating a sustainable future for the automotive industry.Automatic Packing Line

[title_words_as_hashtag