Check out the leading manufacturer for a professional coil packing solution here:

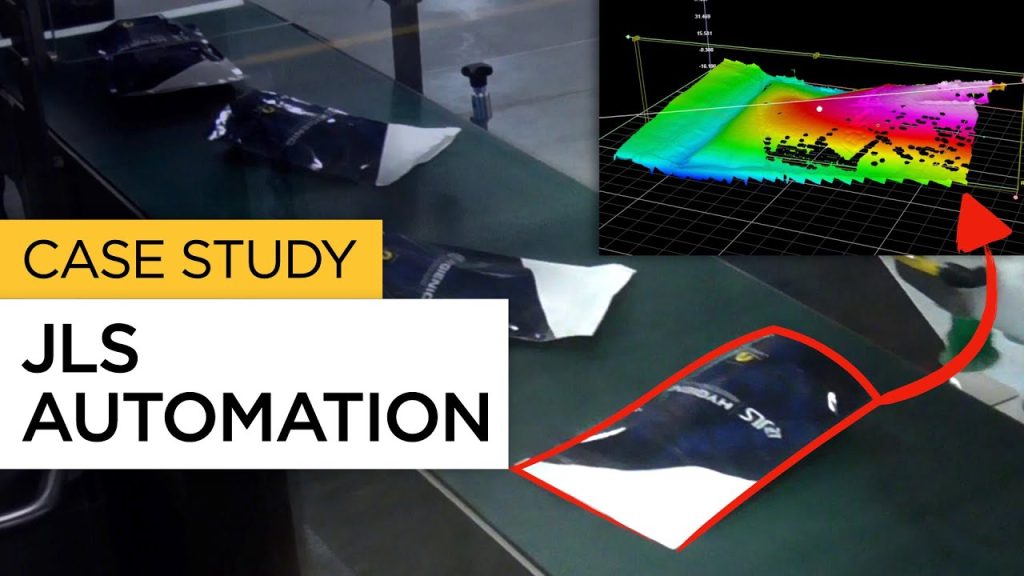

In this application, we will be showcasing JLS Automation’s state-of-the-art vision-guided robotic packaging systems and their utilization in the food packing industry. These advanced systems provide inline product dimensioning and ensure accuracy and efficiency throughout the packaging process.

Food packing is a critical aspect of the food industry, ensuring that products are properly sealed and preserved for transportation and consumption. With the increasing demand for packaged food products, manufacturers are constantly looking for innovative solutions to optimize their packaging processes.

JLS Automation’s vision-guided robotic packaging systems are designed to meet the specific needs of the food packing industry. These systems utilize advanced vision technology to accurately measure and dimension products, ensuring precise packaging every time. By integrating robotics and vision systems, JLS Automation offers a comprehensive solution for food packing that enhances productivity and minimizes errors.

One of the key features of JLS Automation’s vision-guided robotic packaging systems is their ability to perform inline product dimensioning. This means that the system can accurately measure the dimensions of each product as it moves along the packaging line. This information is crucial for determining the appropriate packaging materials and ensuring that products are properly sealed and protected.

By automating the dimensioning process, JLS Automation’s systems eliminate the need for manual measurements, reducing the risk of human error and ensuring consistent packaging quality. This not only improves efficiency but also helps manufacturers meet stringent industry standards and regulations.

In addition to inline dimensioning, JLS Automation’s vision-guided robotic packaging systems offer a range of other benefits for the food packing industry. These systems can handle a variety of packaging materials and formats, including trays, cartons, and pouches. They can also be customized to accommodate different product sizes and shapes, making them suitable for a wide range of food products.

Furthermore, JLS Automation’s systems are designed to integrate seamlessly into existing packaging lines, minimizing disruption and downtime during installation. Their user-friendly interface and intuitive controls make them easy to operate and maintain, reducing the need for extensive training and specialized personnel.

With their advanced capabilities and versatility, JLS Automation’s vision-guided robotic packaging systems are revolutionizing the food packing industry. By streamlining the packaging process and ensuring accuracy and efficiency, these systems help manufacturers meet the growing demand for packaged food products while maintaining high standards of quality and safety.

In conclusion, JLS Automation’s vision-guided robotic packaging systems offer a cutting-edge solution for the food packing industry. With their inline product dimensioning capabilities and advanced technology, these systems enhance productivity, minimize errors, and ensure consistent packaging quality. As the demand for packaged food products continues to rise, manufacturers can rely on JLS Automation for their professional coil packing solutions.

Check out the leading manufacturer for a professional coil packing solution here: Packing System

“Revolutionizing Food Packaging: The Future of Robotic Automation in the Food Industry”